LabVantage Pharma – Supporting Digital Transformation

According to Finnish Medicines Agency Fimea, there were 34 Finnish organizations classified as Pharmaceutical manufacturer in Autumn 2021 [1]. From laboratory IT point of view, we can see two broad and distinctive functions in Pharma business: 1) Research & Development and 2) Manufacturing and QA/QC.

Watch this content in a 30 min video (English subtitles)

LabVantage Pharma – Supporting Digital Transformation suomeksi

According to Finnish Medicines Agency Fimea, there were 34 Finnish organizations classified as Pharmaceutical manufacturer in Autumn 2021 [1]. From laboratory IT point of view, we can see two broad and distinctive functions in Pharma business: 1) Research & Development and 2) Manufacturing and QA/QC. Some do all this themselves, while some do just part of them and outsource others. A developer of an active pharmaceutical ingredient (API) may outsource manufacturing process and/or some parts of research and development to contract companies, such as ”CRO” (Contract Research Organization), ”CMO” (Contract Manufacturing Organization) or ”CDMO” (Contract Development and Manufacturing Organization). A contract manufacturer can add value in also other ways than offering a GMP-compliant manufacturing process. For example, Nanoform has a process that utilizes supercritical CO2 for manipulating the particle size distribution of an API, enabling an API developer to enter market more quickly [2]. Whatever your added value in Pharma sector, LabVantage Pharma is a GxP compliant, dedicated Laboratory Information Management System (LIMS) that enables digital and central managing your data and processes.

Research and development of pharmaceutical products

Research and development of new pharmaceuticals is often a project of ca. 10-12 years [3]. In research phase, target proteins are identified and validated, and molecules are innovated that target them [3]. Often, research involves extensive collaboration with universities and other Pharma companies [3]. In following pre-clinical development, a candidate molecule is chosen for clinical trials [3]. The clinical trials prior to entering market, are phase I, II and III, and during those, formulation of final product is being developed. [3]. In addition to traditional organic chemistry-based synthesizing of new APIs, new drugs enter market in other ways too. For example, therapeutical proteins or other macromolecules can be produced via biotechnology and gene technology using microorganisms. A health benefiting substance found and isolated from nature, may also be classified as a pharmaceutical [5]. Vaccines are obviously classified so too [6].

Picture: Formulation projects make Active Pharmaceutical Ingredients (API) into final Pharmaceutical product (such as tablets, solutions, drops etc.)

From a laboratory work point of view, research and preclinical development are “business as usual”. Analytical chemistry methods are applied to synthesized molecules, for example. Potential pharmaceutical effects are researched with cells in-vitro. Even if parts of research are done in universities instead of Pharma company’s own facilities, it is still possible to have the data research data centralized to a system shared with later development phases and even shared by QA/QC departments. A good way to organize research and related laboratory tests is to use LabVantage Pharma LIMS. You can send laboratory work requests directly from LIMS or an external (easier to use) portal. Electronical Laboratory Notebook (ELN) is an integral part of LabVantage Pharma LIMS system. LabVantage ELN is something like a Word and Excel within LIMS. Laboratory results are synchronized real-time to ELN sheets. Research can be organized to projects – experiments or other levels of hierarchy.

In clinical trials phase I, volunteering test persons are needed – and their consent to participate. In phase II, patients are used as test persons. In phase III, even thousands of test persons are needed [3]. LabVantage Pharma -LIMS suits well in clinical trials. It fulfills the Nordic Biobank demands, regarding eg. control of test subjects and their consent. It is then possible to manage the whole trial in the same system: The clinical study/trial as a whole, as well as collection of samples, labeling and storing samples, test subjects, consent, potentially pseudonymizations, destruction of samples.

Data Integrity in Pharma QA/QC

Manufacturing and QA/QC of pharmaceuticals, including environmental monitoring of facilities, is regulated and controlled heavily. European Medicines Agency (EMA) manages GMP guidance [8]. USA’s FDA manages 21 CFR:ssä [9]. Regarding laboratory work, both have regulations for eg. Computerized systems (GMP Annex 11 / 21 CFR Part 11), quality systems and validations. GxP is a general term and stands for ”Good Practices”. Among others, ”GLP” (Good Laboratory Practice) and “GMP” (Good Manufacturing Practice) concern Pharma QA/QC [10]. Non-clinical research and development are concerned not by GMP but GLP regulations [7].

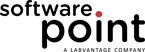

During past decade or so, it is the Data Integrity specifically, that has been amended and iterated several times in GMP Annex 11:n (and CFR 21 Part 11) [11] [12] [13] [14]. USA and EU have both contributed to a comprehensive set of principle regarding Data Integrity, known as ALCOA+ [15]. For example, if a laboratory technician writes down results from a computer screen to a paper notebook: How can it be proven that the result is correct, timestamped correctly, where it is from, that it is complete not missing anything? Digital data in turn must be in human-understandable form, accessible, traceable all the way to raw data etc. During 2010s, inspections by WHO revealed bad practices in data handling, even conscious frauds were found [13]. A concept of temporary memory was introduced: Have the result data been modified before entering to an Excel cell, to paper form ending up in physical archive or other means of permanent record? LabVantage Pharma complies to GxP:n, GMP Annex 11:n and CFR 21 Part 11:n throughout, also the updated Data Integrity concerns, and it even has taken into account the mentioned temporary memory problem. LabVantage and Software Point constantly follow Pharma business and its regulation global development. Audit Trail is an automatic log, saving details relating to handling of data (creation, modification, deletion, transfer): Who did? What did? When? LabVantage Pharma has Dynamic Audit Trail – i.e.. Audit Trail that logs details also PRIOR TO user saving the data. Each user has their own unique username and password. Electronical signature (E-Sign) is used to authenticate users. System will know, who is handling data. Users are given roles or job types that allow them only to see and do necessary things in the system. For example, only managers may be allowed to modify data, or approve batch results. Department specific data can be protected from other departments.

Validation of Information Systems - LabVantage Pharma reduces effort and saves time

GAMP 5 guide by ISPE (International Society for Pharmaceutical Engineering) is guide for validation of computerized systems [16]. LabVantage and Software Point also validate based on it. We understand, that implementing and validating any new information management system to a GxP environment is inevitably a laborious project. LabVantage Pharma is a configurable ready software that helps that effort as much as possible. Our customers receive a full package of executed pre-validation documentation (URS, Traceability Matrix, Validation plan, IQ, OQ, PQ) and templates. Some of this material can be readily used as part of the final validation in the final environment. Some of it can be used as a guidance, help or template when creating one’s own quality documentation.

Picture: Pharmaceutical research, development, manufacturing and quality assurance are heavily regulated and controlled by authorities.

LabVantage Pharma supports all laboratory processes

In the following, I will describe workflows and digital information management needs phased in QA/QC or R&D of a pharma company. LabVantage Pharma is a dedicated software for managing all that. Even ”Out-of-the-Box” (before customer-specific configuration by Software Point professional teams), its functionalities support these. In short, it supports GxP compliant data management and efficient organizing of laboratory work.

Batch (or Lot) management is the most important entity for QA/QC. To sell the product batch, quality of batch must be proven. Representative samples must be taken from final product and often also after different manufacturing process steps. All samples must pass quality tests, including chemical and microbiological analysis, confirming quality and safety of the product. Different products have different physical, chemical or microbiological qualities tested and with different limits or specifications. Raw material batches need quality assurance too. Genealogy between raw materials and end products is important. Often, batch management is done in production ERP system. The same ERP or its add-ons might be used for trying to manage laboratory processes as well. LabVantage Pharma has the described batch management functionality. It can automate creation of batch-based samples and assignment of correct tests, based on batch and product setups. LabVantage Pharma is routinely integrated to different ERP systems. From technical point of view, integration can be done with any modern interfacing technologies (such as REST-API etc). From functional point of view, there are options for what the production ERP does and what LabVantage Pharma does. For example, ERP can initiate a process in LabVantage, creating batch, necessary samples, tests. LabVantage can inform ERP of batch release, or batch release and related reports can be managed via ERP.

Picture: LabVantage Pharma enables proving the quality and safety of manufactured Pharmaceutical product batches.

Sample lifecycle management basically means that all steps done to batch samples are digitally trailed in LIMS. Samples need to be created (can be automated with batch management). They need to be collected, received, potentially packaged, sent further, and stored temporarily and/or for longer period. Samples may face several pretreatment steps and several tests or measurements (or analysis). Tests can be parallel, consecutive and interdependent. Basically sample are in different statuses (”waiting for receival”, ”received”, ”being tested”, ”ready”). Samples may need to be concentrated, diluted, aliquoted, pooled. For traceability, samples should be labelled (usually with bar codes). Samples need to be disposed of so, that their data is still retrievable in data system later. LabVantage Pharma manages all this.

Stability studies [17] [18] purpose is to prove product quality and safety after a period of time, stored under defined conditions (rH-%, 0C). Some drugs are stored in pharmacies, homes or hospitals, in room temperature, refrigerators or freezers. Stability testing can be in normal storing conditions or accelerated conditions. Storing time can be months or several years. Samples (”pulls) need to be taken in defined intervals. Managing the described without a dedicated information system might be challenging: where are each stability study samples stored, how long have they been stored, who and when collects next pulls etc. Sufficient amount of sample in sufficient number of vials or other containers must be stored, so that there is enough sample for all pulls during the study. LabVantage Pharma has a ready set of functionalities for managing the whole of stability studies.

Inventory and storage management – Chemicals, Reagents, Consumables

In addition to samples, laboratory needs to store all other necessary materials: purchased chemicals, house-made reagents, buffer solutions etc., Agar plates, gloves, chromatography columns, what not. Chemicals and reagents may need a quality check before they can be used. Storage containers may need to be managed on many levels (facility, room, freezer, rack...). Supplementary purchase of supplies is needed when approaching out of stock. LabVantage Pharma enables data management for all this.

Method development and execution

Test and analysis methods are validated and need to be managed and be ready to be executed, preferably from a digital library. In a LIMS system, they part of Master Data. Methods can be applied from accredited EN methods, or they might need to have developed in-house. Before using, a method needs to be validated, ie. prove and document that the method repeatably gives accurate results. Methods include laboratory work steps, such as pipetting, centrifuging, instrumental chemical analysis. Methods have a total uncertainty calculated from its steps. LabVantage Pharma allows managing all method details comprehensively, and it can also be used for method validation. For execution of methods for real life samples, LabVantage Pharma offers an Electronical means of step-by-step guided and documented method execution. We call it LES = Laboratory Execution Sheet. LabVantage Pharma supports use of mobile devices. Working with LES allows sample results and other data to be in accordance with ALCOA+ principles, not being dependent on temporary notes on printed paper, or hand-written results.

Picture: LabVantage Pharma's electronical Laboratory Execution Sheet (LES) can be used with mobile devices or computers - This adds on in Data Integrity according to ALCOA+ principles.

Results from instruments

The previous sentence brings us to getting results automatically and traceably directly from the instruments or equipment. From data integrity point of view, it is best if human hand never touches the results: not the raw data nor the calculated or refined results. LabVantage Pharma, with its LabVantage Connect and SDMS (Scientific Data Management System). For simple devices like balance or pH meter, a result is collectable by clicking on the data entry screen in LabVantage Pharma. With HPLC, ICP, or more complicated instruments, LabVantage Pharma is used for managing sample batch or set that is sent to the instrument; and then retrieving results from the instruments. Both steps can be automated. Chromatography or ICP runs are sequences or batches, that also include Analytical Quality Control (AQC) samples (sufficient number of 0 controls, other controls, spikes etc). LabVantage Pharma also manages the AQC part and related control cards. Also statistical process control is part of LabVantage [19]. Refining results to final quality report may include several approval and review steps. If samples are within spec limits, approvals can be automated. If spec limits are not met (OOS situation), a CAPA investigation can be initiated automatically. In addition to numerical results, some results may be qualitative or need human interpretation for some reason. LabVantage Pharma enables picking a textual result from a predefined list (such as color) and/or field for free writing. For additional descriptions, interpretations or comments, a standard sentences library can be used to facilitate writing by suggesting.

Environmental monitoring (EM) is an essential and mandatory part of GMP-regulated activities [20]. For ISO classified clean rooms, their control systems mainly take care of pressure difference control, temperature and moisture data collection. For clean rooms and all other facilities under GMP regulation, the laboratory’s task is mainly to collect and analyze microbiological samples from air, surfaces and textiles. Microorganisms must be identified and quantified per dead or viable counts. Location and collection time are used for trending EM results. These activities involve sample collection plan and managing sampling locations (maybe in a map and/or pictures of the rooms). Again, digital support for all this is ready in LabVantage Pharma.

LabVantage Pharma facilitates organizing laboratory work and resources

As a recap: Laboratory may receive samples and work request from research or development projects; and raw material or end product batch quality assurance. Such request is an entity containing one or several samples, each with assigned tests. Samples may have due dates from collection to all tests ready. Some laboratory work might need to be done by different persons. Laboratory workers need to be trained for what they do. Chemicals and reagents need to be qualified. Instruments need to be validated, calibrated, certified, maintained.

LabVantage Pharma lets you assign and organize all work, for example to ”to do lists” per department, worker, instrument and method. Dashboards will show the situation in the laboratory: How many samples under work, throughput time per department, etc. Calendar views can be used to help divide workload.

LabVantage Pharma and Business Intelligence (BI)

From 2010s, discussion has increased around topics such as BI, Data analytics, Big Data, Data Lakes. Artificial Intelligence (AI) is often being flashed even when referring to very narrow applications or even programmed automation or algorithms. LabVantage Pharma is a LIMS system, collecting, storing and organizing digital data in a database format. It can be combined to LabVantage’s own or other developers’ BI tools. Then meaningful information can be automatically visualized from latge amount of stored data. When referring to laboratory digitalization, traditionally this has meant replacing paper with computers. However, a more modern term is ”Digital Transformation”. That is used to refer to an aim of having all organization’s data available in a centralized place. This is challenging in many ways, not only because data (in data lakes for example) should be harmonized when it is collected from various sources in various forms. A single IT company can obviously not solve a large organization’s total digital tranformation, but LabVantage Pharma makes a large contribution, as described in this blog post. LabVantage constantly develops several things, including Data Analytics tools. Also we at Software Point keep ourselves updated what the future brings to us!

Writer: Jype Multanen

The writer is an Account Manager at Software Point – LabVantage Nordics, responsible of sales to new customers. His education Master of Science (Tech), majoring in Bioprocess Engineering in Helsinki University of Technology.

REFERENCES AND LINKS:

[1] https://www.fimea.fi/valvonta/laaketehtaat_ja_-tukkukaupat/toimiluvat/kotimaiset_laaketehtaat (linkki katsottu 18.12.2021).

[2] https://nanoform.com/en/technology/ (linkki katsottu 18.12.2021).

[3] https://sic.fimea.fi/4_2014/laakekehitys_eilen_tanaan_ja_huomenna

[4] https://www.fimea.fi/valvonta/kliiniset_laaketutkimukset (linkki katsottu 28.12.2021).

[5] https://www.fimea.fi/valvonta/luokittelu/luokittelupaatoksia (linkki katsottu 28.12.2021)

[6] https://www.fimea.fi/vaestolle/rokotteet

[7] https://www.fimea.fi/valvonta/glp-valvonta

[8] European Commission - Health and Consumers Directorate-General; EudraLex - The Rules Governing Medicinal Products in the European Union - Volume 4 - EU Guidelines for Good Manufacturing Practice for Medicinal Products for Human and Veterinary Use; https://ec.europa.eu/health/documents/eudralex/vol-4_it

- Chapter 1: Pharmaceutical Quality System

- Chapter 4: Documentation

- Chapter 6: Quality control

- Annex 11: Computerised Systems

- Annex 15: Qualification and Validation

[9] U.S. Department of Health and Human Services – Food and Drug Administration; CFR – Code of Federal Regulations Title 21; https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm

- Chapter 1, Part 11, Electronic records and electronic signatures”

- Chapter 1, Part 58, Good Laboratory Practices (GLP) for non-clinical studies.

- Chapter 1, Part 211, Current Good Manufacturing Practice (cGMP) for Finished Pharmaceuticals,

[10] https://en.wikipedia.org/wiki/GxP

[11] U.S. Department of Health and Human Services – Food and Drug Administration - Center for Drug Evaluation and Research (CDER) & Center for Biologics Evaluation and Research (CBER) & Center for Veterinary Medicine (CVM), Data Integrity and Compliance With CGMP Guidance for Industry, Draft Guidance,

2016: www.fda.gov/down_loads/drugs/guidances/ucm495891.pdf

[12] U.S. Department of Health and Human Services – Food and Drug Administration - Center for Drug Evaluation and Research (CDER) & Center for Biologics Evaluation and Research (CBER) & Center for Veterinary Medicine (CVM), Data Integrity and Compliance With CGMP – Questions and Answers – Guidance for Industry; December 2018.

[13] Data Integrity in the Pharma Space – Advanced Informatics Solutions for Digital Data Management; White paper by Labvantage Solutions, Inc; Downloaded 18th Dec 2021 from: https://www.labvantage.com/knowledge-center/white-papers/data-integrity-in-the-pharma-space/.

[14] Understanding the Regulations and How LabVantage Successfully Helps Customers Comply With These Requirements – LabVantage and 21 CFR Part11/ Annex 11 Compliance; White paper by Labvantage Solutions, Inc; Downloaded 18th Dec 2021 from: https://www.labvantage.com/pdfs/knowledge-center/white-papers/Pharma-LabVantage-and-21-CFR-Part-11-Annex-11-Compliance.pdf

[15] https://www.gmp-compliance.org/gmp-news/alcoa-what-does-it-mean

[16] https://ispe.org/publications/guidance-documents/gamp-5

[17] U.S. Department of Health and Human Services – Food and Drug Administration – Center for Drug Evaluation and Research (CDER) & Center for Biologics Evaluation and Research (CBER); Guidance for Industry - Q1E Evaluation of Stability Data; 2014.

[18] WHO Technical Reports Series, No. 1010, 2018; WHO Expert Committee on Specifications for Pharmaceutical Preparations – Annex 10: Stability testing of active pharmaceutical ingredients and finished pharmaceutical products.

[20] An Introduction to Trending in Environmental Monitoring Programs; Guest Column by Crystal M. Booth in OUTSOURCED PHARMA, April 5, 2021.

International Society for Pharmaceutical Engineering, GAMP Guide.

Positioning Your Pharmaceutical Lab for Success - A Case for the Purpose-built Laboratory Informatics System; Downloaded 18th Dec 2021 from: https://www.labvantage.com/knowledge-center/white-papers/positioning-your-pharmaceutical-lab-for-success/