MOWI

Industry

Food & Feed

MOWI

Beneath the surface

Mowi is one of the largest seafood companies in the world, and the world’s biggest producer of Atlantic salmon – satisfying one fifth of global demand.

Mowi operates the entire value chain from fish feed to whole gutted fish, premium fish fillets and steaks, ready-to-eat products like smoked salmon and portioned fish. The product portfolio comprises salmon, and elaborated seafood, fresh or frozen. The harvest volume of the flagship product salmon alone was 381,000 tons (GWE, gutted weight equivalent) last year.

Grown over decades organically as well as by acquisitions and mergers, Mowi now has a turnover of EUR 3.6 billion, more than 12,700 employees in 24 countries, and farming activities in Norway, Scotland, Canada, Chile, Ireland and the Faroe Islands. The company´s laboratory information management system – LabVantage Enterprise LIMS provided by Software Point, LabVantage Nordics – is flexibly adapted as the organization grows.

Gaining more muscles

The life cycle of salmon starts in freshwater and involves several stages before the smolts are moved to the sea. A salmon that´s ready for harvesting weighs about five kilos, and it takes three years for the salmon to get that big.

The life cycle of salmon starts in freshwater and involves several stages before the smolts are moved to the sea. A salmon that´s ready for harvesting weighs about five kilos, and it takes three years for the salmon to get that big.Healthy fish is a matter close to Mowi´s heart. To ensure high-quality and tasty products the company is conducting thorough analysis and quality assurance. The verification process is carried out partly with the samples, partly online monitoring.

“We have at least 20,000 listeria monocytogenes analysis annually, and that’s only one of the analyses. In 2016-2017 there will be about 62,000 microbiological samples entered in the laboratory information system. Also, we use LIMS to keep results from our surveillance program on undesirable substances in fish and feed”, describes Randi Haldorsen, Group Technical Manager Food Safety & Quality.

Recently, Mowi established integration with its main lab supplier for micro, chemical and contaminant analyses. Orders are exported and complete analysis imported using Mowi´s LabVantage laboratory information management system (LIMS).

“We send our orders to our main laboratory and it coordinates the tasks with the networking laboratories. When a laboratory receives our order, together with our results based on codes, the laboratory knows what kind of analysis should be done as the information is automatically imported from the system. Also, we get research information background when registering a sample in LIMS.”

“It speeds up the approval process: instead of many manually entered results, we get the results automatically. We just need to check and approve them.”

Becoming a superuser

The most important reason for Mowi acquiring LabVantage LIMS was the need for one common system. Earlier, the system was used in one part of the growing company.

“We use LIMS for standard reporting – microbiology results, monitoring food products and water quality – to our customers and authorities, as well as for trend analyses to ourselves: are we in line where we want to be right now, and differences between business units”, Randi Haldorsen says.

The benefit of having this system is that you can take out quick reports. With LabVantage LIMS you can easily edit sample results, and there are various ways to work more effectively when you are a superuser.”

Haldorsen sees that the most important part in the project is to first figure out exactly what kind of information you want out of LIMS.

“Our system is quite detailed. I think implementation is the hardest part as you need to add a lot of info into LIMS. After you have learned the way the system is built, how it works and you know all the tricks, it is much easier to register different samples. There are many tools to make your work more efficient.”

According to Haldorsen, it is worth thinking and digging out, from time to time, what you are aiming at and why you make changes in the system.

“I try to understand the consequences – whether a change should be done this way or another. Software Point handles smaller and bigger developments such as e.g. integrations with laboratories or changing forms. Basically helping us evolve the system, keeping it modern and continuously extending the expected lifespan.”

All is fish that comes to the net

Today, LabVantage LIMS is actively used in 15 Mowi factories. In addition to the technical and laboratory people, LIMS is used in R&D to some extent.

Today, LabVantage LIMS is actively used in 15 Mowi factories. In addition to the technical and laboratory people, LIMS is used in R&D to some extent. Leading the “Blue Revolution”, Mowi has been at the forefront of developments in the aquaculture industry.

“In my team within the Global R&D and technical department, we are conducting various projects to improve our products, to achieve even better quality. We have high focus on hygiene. We also use LIMS for registering nutritional facts, like fat and fatty acids as well as color”, Haldorsen relates.

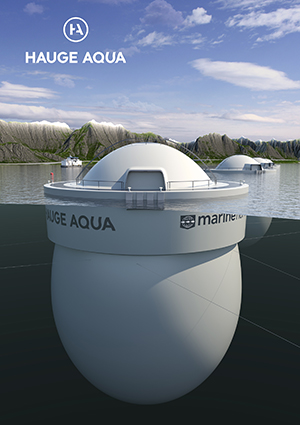

The fish farming industry across the globe is striving for producing sustainable feed and food, and finding new ways of producing salmon in the sea.

“Our foundation is based upon the belief that by farming the ocean, we can sustainably produce healthy, nutritious and affordable food for society at large. While 70% of our planet is covered by water, the United Nations Food and Agriculture Organization (FAO) estimates that only around 2% of the world’s food supply comes from the ocean. This includes both farmed and wild-caught fish.”

“We believe that global consumption of farmed seafood will increase in the future, both in terms of overall volumes and as a percentage of the global food supply.”

More info: www.movi.com

Text: Software Point

Photos: Mowi

16.8.2017 – Company name updated from Marine Harvest to Mowi 11.11.2021